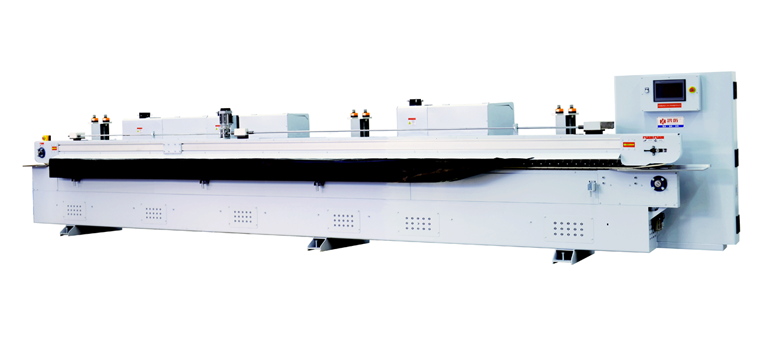

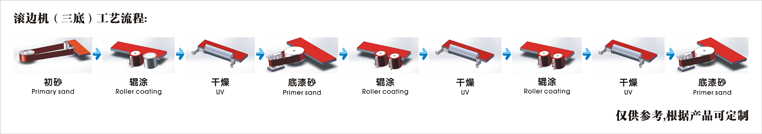

滾邊機 (三底)

型號:HL-G100A

HL-G100A

UV滾邊機是一種專為木器、塑料、金屬、建筑新材料等材料邊部涂布設計的自動化設備,通過輥輪與UV涂裝技術實現高效加工。

核心功能

采用輥輪結構完成材料側邊毛料的砂光、涂布及干燥,實現從毛料到面漆的一體化加工,顯著減少打磨噴漆工序。適用于木器、塑料、金屬、建筑新材料等多種材料,處理后表面光滑、漆膜飽滿且無色差。

技術特點

結合UV涂裝技術,通過紫外線固化提升漆膜附著力和耐久性。

應用場景

主要用于實木家具工廠、新型建筑材料加工廠等需要高效表面及邊部處理的領域,提升生產效率并降低人工成本。

設備優勢

一體化加工流程減少中間環節,縮短生產周期。精確控制涂布厚度和邊緣質量,滿足多樣化工藝需求。

UV edge rolling machine is an automated equipment designed specifically for edge coating of materials such as wood, plastic, metal, and new building materials. It achieves efficient processing through rollers and UV coating technology.

core functionality

The roller structure is used to complete the sanding, coating, and drying of the side wool of the material, achieving integrated processing from wool to topcoat, significantly reducing the polishing and painting process. Suitable for various materials such as wood, plastic, metal, and new building materials. After treatment, the surface is smooth, the paint film is full, and there is no color difference.

Technical Features

Combined with UV coating technology, the adhesion and durability of the paint film are improved through UV curing.

Application scenarios

Mainly used in solid wood furniture factories, new building material processing factories and other fields that require efficient surface and edge treatment, to improve production efficiency and reduce labor costs.

Equipment advantages

The integrated processing flow reduces intermediate links and shortens the production cycle. Accurately control coating thickness and edge quality to meet diverse process requirements.

展廳:佛山市順德區紅力機械設備有限公司

展廳:佛山市順德區紅力機械設備有限公司 工廠地址:佛山市順德區倫教街道新塘村世龍集約工業區世龍大道27號之2

工廠地址:佛山市順德區倫教街道新塘村世龍集約工業區世龍大道27號之2

服務熱線:+86 0757-27751889 (20條服務熱線)

服務熱線:+86 0757-27751889 (20條服務熱線)

公司網址:

公司網址: